Our readers have varying degrees of familiarity with the terms “digital models” and “digital twins,” from experts to novices and everything in between. People and companies like to bandy these words about under the general rubric of “digital transformation”, but they rarely define them. In this two-part series, we’ll define what these terms mean. But more importantly, for both technical and non-technical readers, we’ll talk about what digital models and digital twins mean in the context of engineering documents. Even to seasoned experts, digital models and twins don’t usually involve document objects, so the concept needs further description for everyone. We will explain how and why digital models are important to the world of engineering documents and industry standards, and why companies and publishers should consider making a shift in this crucial area of operation.

Part 2 of this series will talk about what engineering documents look like when converted to digital models and dig into some of the benefits.

To be clear, when we use the term engineering documents, we refer to a wide range of document types including internal company specifications, external industry standards, assembly instructions, procurement technical data packages (TDPs), test methods, and supplier requirements, and other similar types.

Typical emotion when hearing the words “digital transformation,” “digital thread,” “digital model,” and “digital twin.”

What is a Digital Model?

A digital model is a virtual representation of a real or imagined object that describes the structure, context, and behavior of that object. Crystal clear, right?!

After creating a digital model of an object, it becomes possible to do simulation, analysis and much more without the need to use actual physical items. The most familiar example is a CAD model which provides a three-dimensional visual representation of a physical object including its geometric dimensions, textures, materials, tolerances, and more. Likewise, a digital model of a building or a part or a system of parts provides all the critical data associated with the object or system.

Manufacturers in particular find digital models to be invaluable because they can test concepts and ideas in unlimited ways before actually spending time or money on production. (I have a dream about doing the same with my cooking: when will I be able to create digital models of my dessert creations without having to mix, bake, and reject the first four iterations?!)

What is a Digital Twin?

A digital twin is a digital model that represents a unique physical (real) asset, and which is dynamically updated with data from the physical asset throughout its lifecycle.

Let’s say that Wingding Aerospace Company builds a digital model of their flagship airplane, a sort of “template” model that represents the most common form and features of their aircraft. They use that model to pitch the airplane to potential customers (showing them all the features in a virtual representation), but each customer ends up purchasing a uniquely different version of the plane. Northern Airlines wants two large ovens instead of three small ones. Eastern Airlines wants upgraded landing gear. Southern Airlines wants a premium stereo system and disco lights throughout the cabin (my kind of airline).

In each case, Wingding builds a digital twin of each aircraft based on the standard digital model and incorporating the unique characteristics of the real physical asset. Each twin inherits the standard characteristics of the Wingding flagship model, but each twin is unique because it incorporates the unique space, wiring, hardware, weight, and other specifications of the individual airplane. Think of a digital twin as your own unique iteration on a classic recipe: my meatloaf has ground beef and sauteed onions, but it also includes a few secret ingredients that make it unique. (Read Part 2 for my secret ingredients).

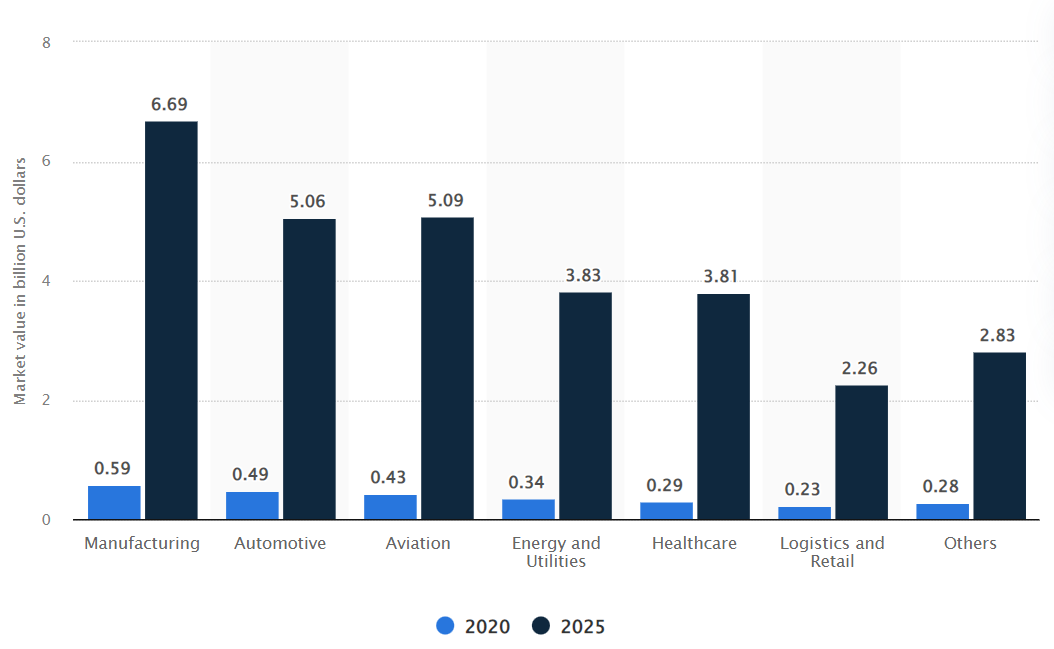

The market for digital twins is expected to increase ten-fold from 2020 to 2025. (Credit: World Economic Forum)

Physical Twins Can Update Their Digital Twins

Credit: Simumatik.

One very important aspect of digital twins takes into account the effect of changes over time.

“Digital twins are of most use when an object is changing over time and when those changes can be correlated with associated data.” These changes could be undesirable, for example the fatigue of landing gear shock absorbers, or more neutral but still important, such as discontinuation of a lightbulb in the disco light system.

As each airline takes delivery of their planes and maintains them over time, the airlines can feed usage and performance data into their digital twins to maintain accurate descriptions of the object or system. The landing gear on the Eastern Airlines plane will wear and fatigue differently than other airplanes. Northern Airlines will need to maintain and procure different parts for their larger ovens. And Southern Airlines may see distinctly different wear patterns on the cabin floors from all the passengers dancing in the aisle. In each case, the airlines will maintain their virtual product as a unique digital twin. A digital twin *is* a digital model, but it is a unique and ever-changing version of the real physical asset. Conversely, a digital twin without a physical asset is just a digital model.

Here’s the Rub (and the Pain)

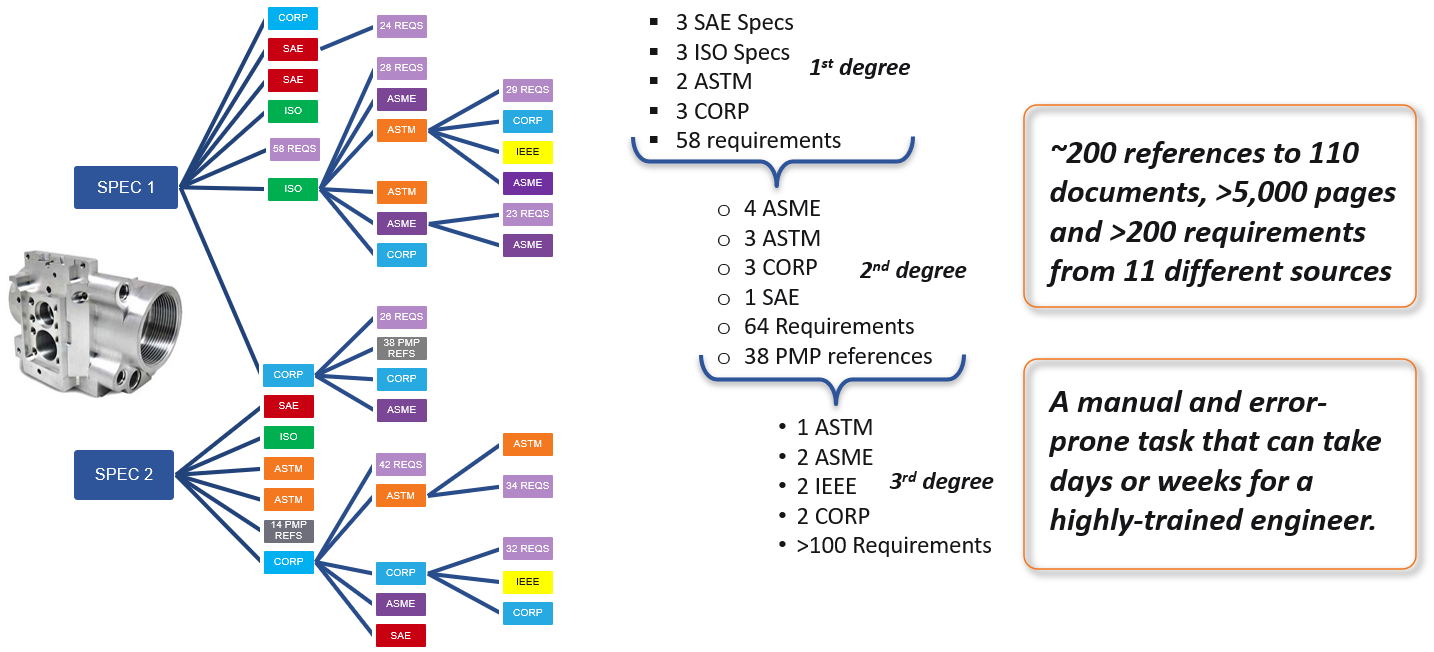

Throughout a product development lifecycle and over the course of a product’s lifetime in-the-field, the producer or owner must manage a long list of varied and changing requirements distributed across multiple authoritative sources from inside and outside the enterprise. Knowing what those changes are and knowing how they impact their product or operation is a dual task called change management and impact assessment. A related process of identifying requirements for implementation is often called requirements management.

For example, when Eastern Airlines orders a plane with the upgraded landing gear, or when a new standard is published that affects a product under development, the changes can affect dozens or hundreds of parts, materials, or processes, and require significant design and engineering modifications downstream. Since the mid 1990s, these changes have been published most commonly as PDF documents. It may be a single standalone document or an entirely new specification summarized in a TDP (Technical Data Package). One technician can spend hours or days wading through PDF documents, identifying the changes, assessing their impact on relevant areas of the business, and communicating the modifications to appropriate teams, usually by copying/pasting the new requirements into new documents like work instructions, assembly instructions, internal corporate specifications, and more. The time, knowledge, and seemingly bottomless patience required for this task is monumental. As a result, the process of change management, impact assessment, and requirements management are often saddled with long delays, duplicative work, and human errors.

In an ideal world, we would automate these tasks and teach software and machines to do the work. Imagine a machine that could analyze engineering documents and industry standards and not only highlight changes from the previous versions, but provide intelligent instructions on how the changes impact product development, and prescribe the steps needed to accomplish the changes. A trained machine could even raise alarms for potential troubles down the road such as hard-to-find parts or materials, long lead-time components, hazardous materials, regulatory requirements, price spikes in specified parts, and much more.

Unfortunately, PDF documents are not machine readable so the automation scenario is not widespread and requires significant software training. To a machine, the text, tables, graphs, images, and equations contained in PDF documents are merely characters laid out in random order, without context and meaning. Furthermore, nearly every author of an engineering document lays their characters out in different ways. Industry standards in particular are highly unstandardized, but this problem also exists among OEMs and suppliers across any one particular industry. (The aerospace industry has challenged its members to develop a standardized model of digitally compatible information, outlined in a paper by AIA’s Future of Aerospace Standardization Working Group (FASWG).)

We can teach machines to read PDF – something that is already underway in the SWISS platform – but a much more efficient solution is to transform documents from flat “dead-text” artifacts into intelligent digital models that describe the structure, context, and behavior of the information contained therein.

So What Now?

By now, I hope you are salivating at the potential benefits of transforming engineering documents into a format compatible with digital models and the Digital Thread. But if you’re not, don’t worry, we’ve laid it all out in Part 2 of this article.

Part 2 will show you how the concepts of digital models can be applied to engineering documents, industry standards, product engineering, change management, and requirements management, resulting in lower costs, faster cycle times, and reduced risk.

And of course, you’ll learn the secret ingredients in my meatloaf 😉